GX-M SERIES

Linear Motor Driven

Laser Cutting Machine 1500W-6600W

HSG-NEST Nesting Software

Rear Floorstand Installed Together with Machine Bed

Double Exchange Platforms, Taper Pins Positioning

Five-stage Piercing and Perfect Finish Cut

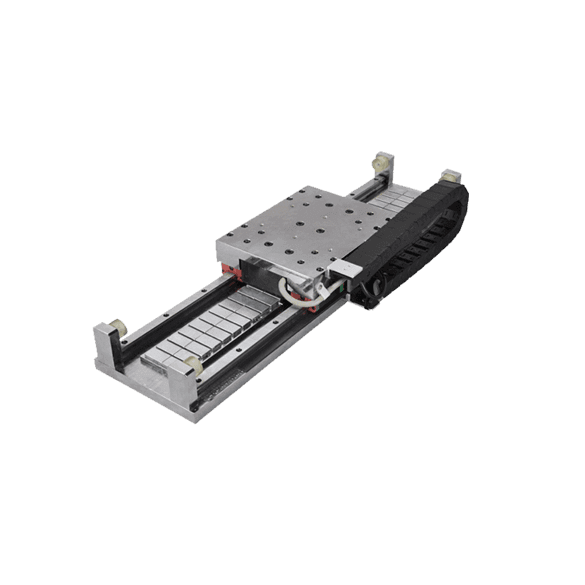

Linear Motor

No-load speed 180m/min

Acceleration 2.0G

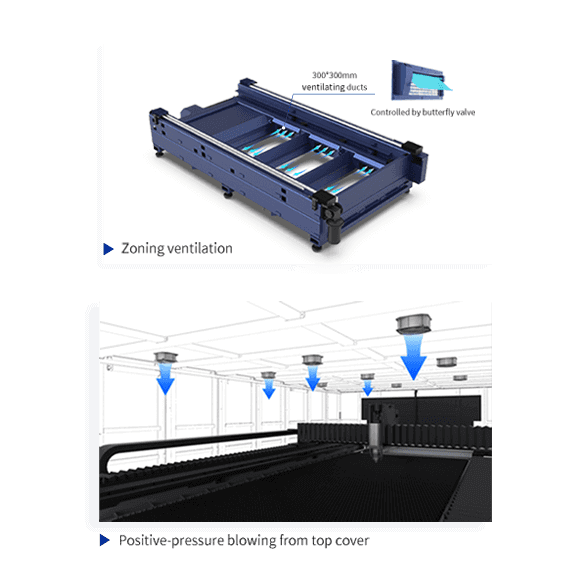

Zoning Ventilation

Divide cutting area into left and right zone

Generally controlled by butterfly valves

300*300mm large-caliber ventilating ducts

Send positive-pressure gas to cutting area from top cover to press down cutting smoke below machine bed

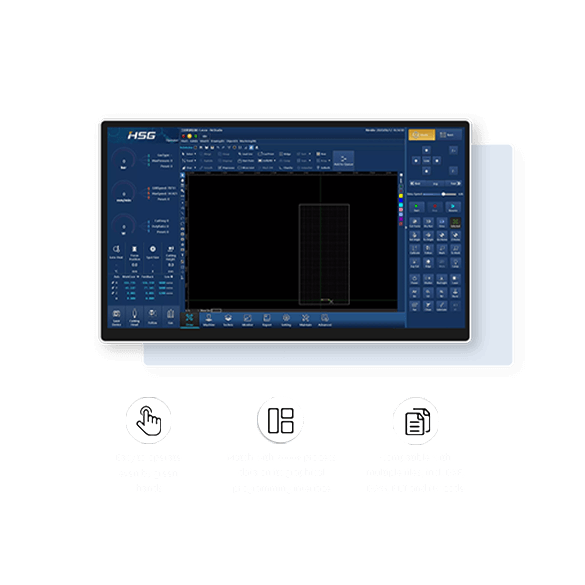

Alpha T Bus CNC System

Alpha T can make data transmission via a network cable.

Micro-connection cutting

Active obstacle avoidance

Real-time monitoring of core components

Active reminder of machine maintenance

HSG-NEST nesting software

*Bus refers to data transmission mode via on-site bus control system.

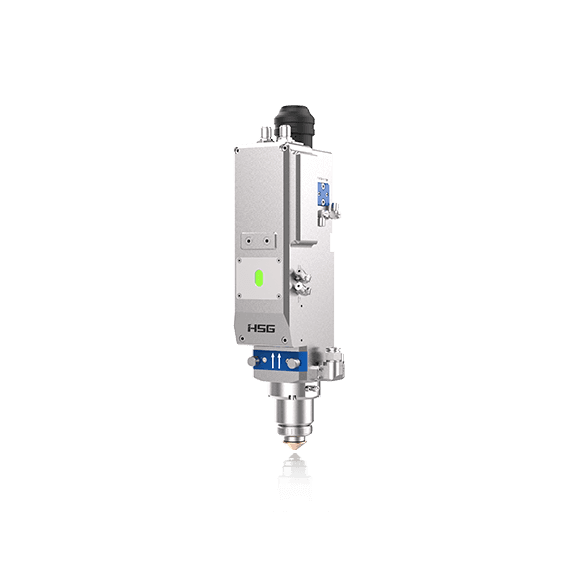

Autofocus Laser Cutting Head

The cutting head can adjust its focus according to laser beam mode to make sure of mirror-like surface.

Autofocus accuracy ±0.01mm by servo autofocus system

Automatic cooling and obstacle avoidance

Three built-in protective lens

Anti-pollution design

Give early warning if abnormal

Technical Parameter

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine.

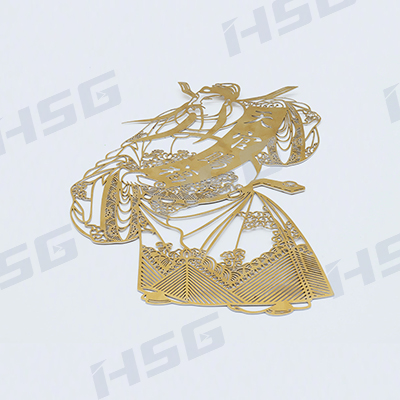

Cutting Samples