GC III-H / BEVEL-GCIII-H Series

High-power Laser Cutting Machine 12000-20000W

Cut Both Plain Incision and 45° Bevel

Extruded Aluminum Beam

Gantry Plate-welded Machine Bed

German WITTENSTEIN Alpha Speed Reducer

Cutting Capability

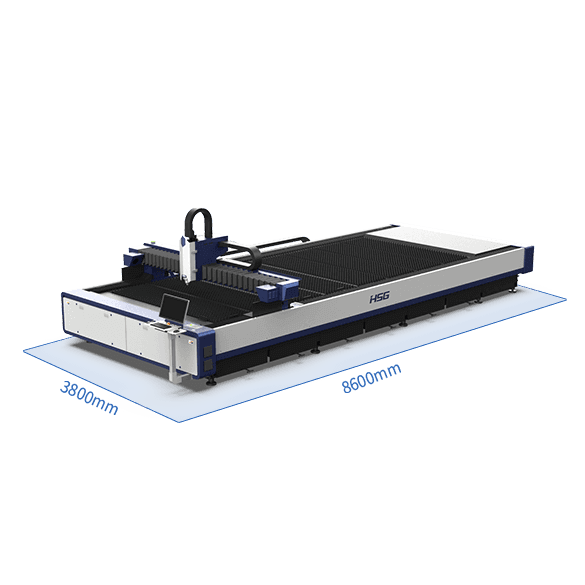

*Overall dimensions (L*W*H) 8600*3800*1700mm (6000*2500mm) thanks to its single platform

*12000-20000W, with the ability of cutting 13000*3000mm and 80mm thick sheet

Positioning accuracy up to ±0.05mm

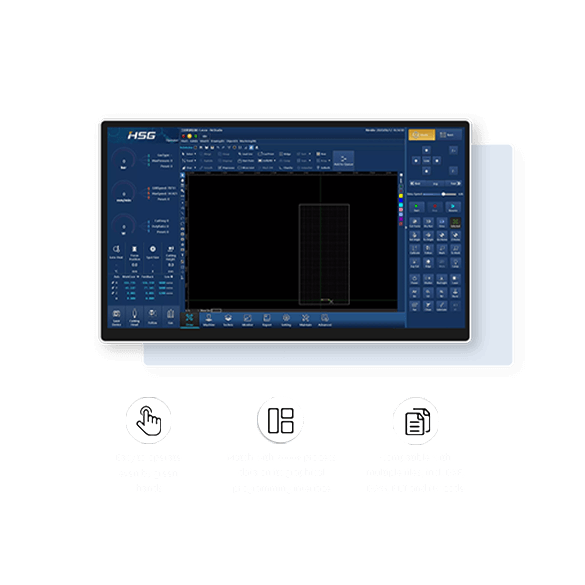

Alpha T Bus CNC System

Alpha T can make data transmission via a network cable.

Micro-connection cutting

Active obstacle avoidance

Real-time monitoring of core components

Active reminder of machine maintenance

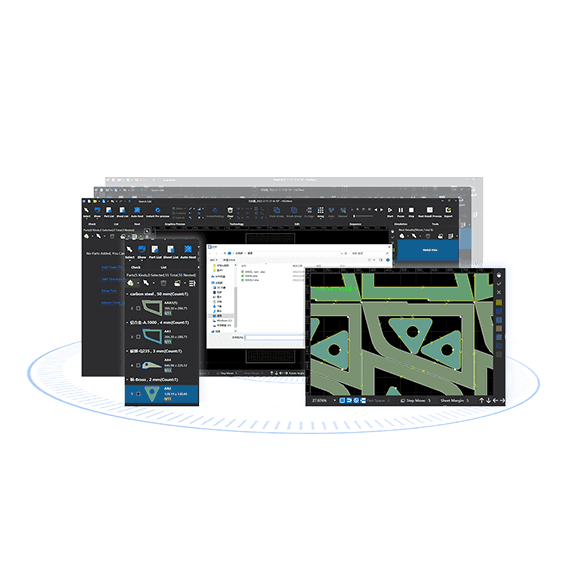

HSG-NEST nesting software

*Bus refers to data transmission mode via on-site bus control system.

Once Forming of 45° Bevel

P10/P20 cutting head works in conjunction with Alpha T bus CNC system to break through conventional 0° straight section and make 45° bevel possible.

HSG-NEST Nesting Software

HSG-NEST works as a standalone and network-free software. Nesting will start instantly after inputting parts graphics, message and sheet size. Relevant machining reports are also available to be output.

P10/P20 Autofocus Laser Cutting Head

It can change its laser spot to proper size and shape according to cutting materials and thickness.

Active obstacle avoidance, automatic cooling down

Optical filming, visual display of temperature and pressure

Anti-pollution design, cut with mirror-like surface

Remind of regular maintenance, give early warning if abnormal

Technical Parameter

| MODEL | G6025C III-H | G8025C III-H | G12025C III-H | G13030C III-H |

|---|---|---|---|---|

|

Power

|

12000W-20000W

|

12000W-20000W

|

12000W-20000W

|

12000W-20000W

|

|

Working Area (L*W)

|

6000*2500mm

|

8000*2500mm

|

12000*2500mm

|

13000*2500mm

|

|

X/Y-axis Positioning Accuracy

|

±0.03mm/m

|

±0.03mm/m

|

±0.05mm/m

|

±0.05mm/m

|

|

X/Y-axis Repositioning Accuracy

|

±0.03mm

|

±0.03mm

|

±0.05mm

|

±0.05mm

|

|

No-load Speed

|

100m/min

|

100m/min

|

100m/min

|

80m/min

|

|

Acceleration

|

1.0G

|

1.0G

|

1.0G

|

0.8G

|

|

Loading Weight of Platforms

|

5900kg

|

7800kg

|

11700kg

|

15300kg

|

|

Overall Dimensions (L*W*H)

|

8600*3800*1700mm

|

11000*3800*1700mm

|

15600*3800*1700mm

|

16800*4400*1700mm

|

| MODEL | BEVEL-G6025C III-H | BEVEL-G8025C III-H | BEVEL-G12025C III-H | BEVEL-G13030C III-H |

|---|---|---|---|---|

|

Power

|

12000W-20000W

|

12000W-20000W

|

12000W-20000W

|

12000W-20000W

|

|

Working Area (L*W)

|

6000*2500mm

|

8000*2500mm

|

12000*2500mm

|

13000*3000mm

|

|

X/Y-axis Positioning Accuracy

|

±0.05mm/m

|

±0.05mm/m

|

±0.05mm/m

|

±0.05mm/m

|

|

X/Y-axis Repositioning Accuracy

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

|

No-load Speed

|

80m/min

|

80m/min

|

80m/min

|

80m/min

|

|

Acceleration

|

0.5G

|

0.5G

|

0.5G

|

0.8G

|

|

Loading Weight of Platforms

|

5900kg

|

7800kg

|

11700kg

|

15300kg

|

|

Overall Dimensions (L*W*H)

|

8600*3800*1900mm

|

11000*3800*1900mm

|

15600*3800*1900mm

|

16800*4400*1900mm

|

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine.

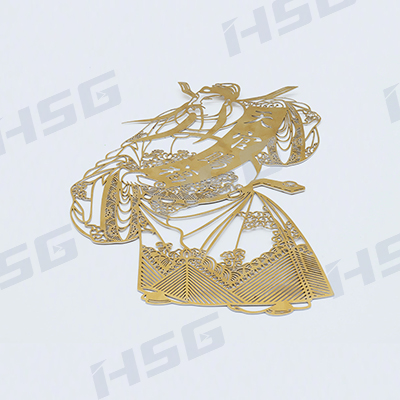

Cutting Samples