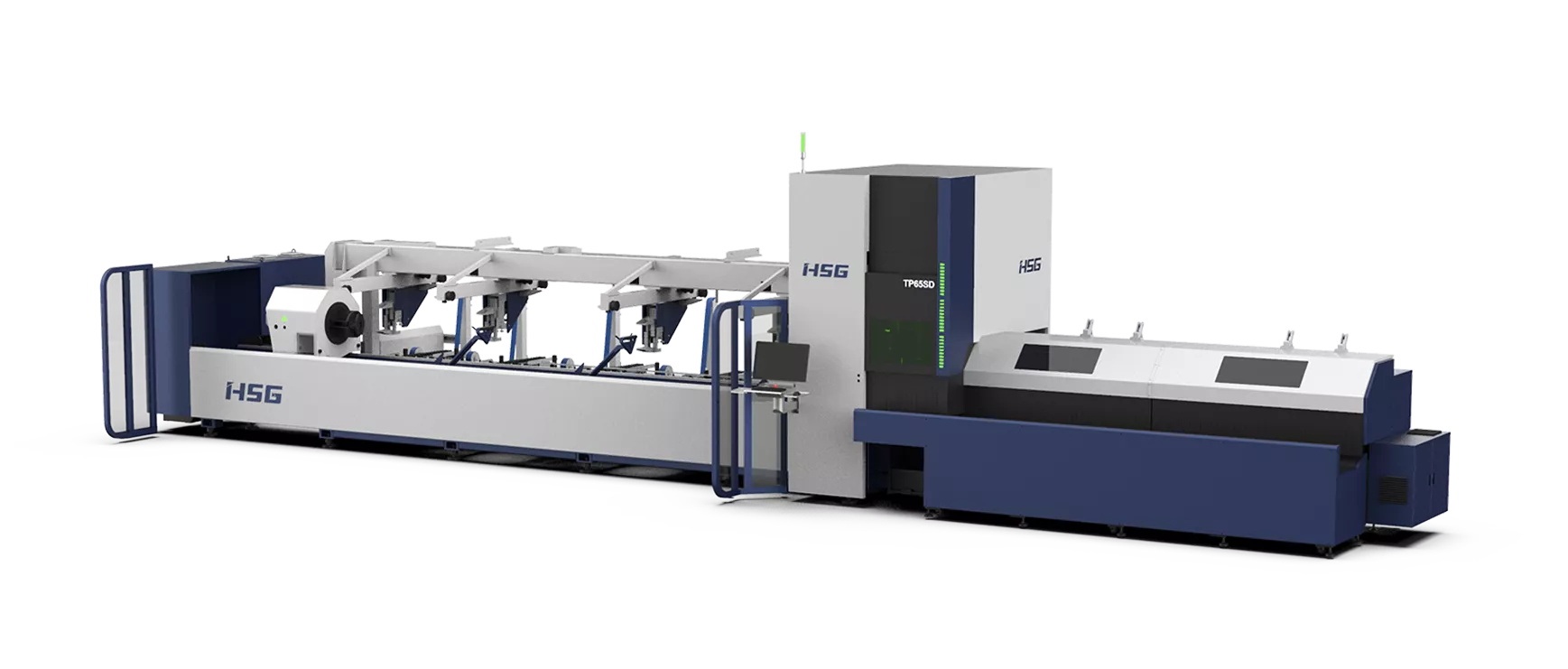

TPSD

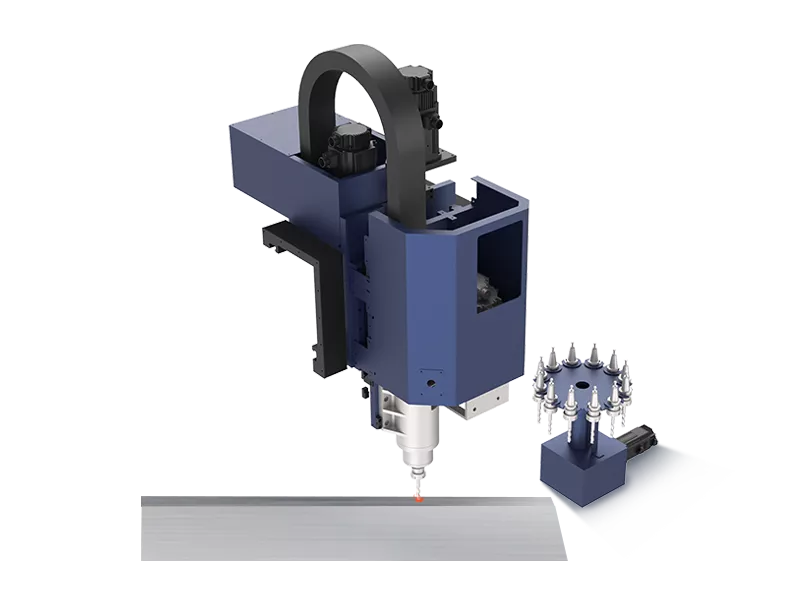

Flagship Series Compound Tube Fiber Laser Cutting Machine With Drilling and Tapping

Efficient Production: Cutting + Drilling + Tapping

Integrated laser cutting, hot melt drilling and tapping, for molding at once to reduce processing processes, save labor, greatly shorten processing time and improve production efficiency

SPEED+ High-speed Tube Cutting Technology

Using SPEED+ high-speed cutting technology to improve the cutting efficiency of dense small graphics for high-speed tube cutting.

* Note: Chuck Rotation Speed: 120r/min

* Chuck Linkage Speed: 120m/min

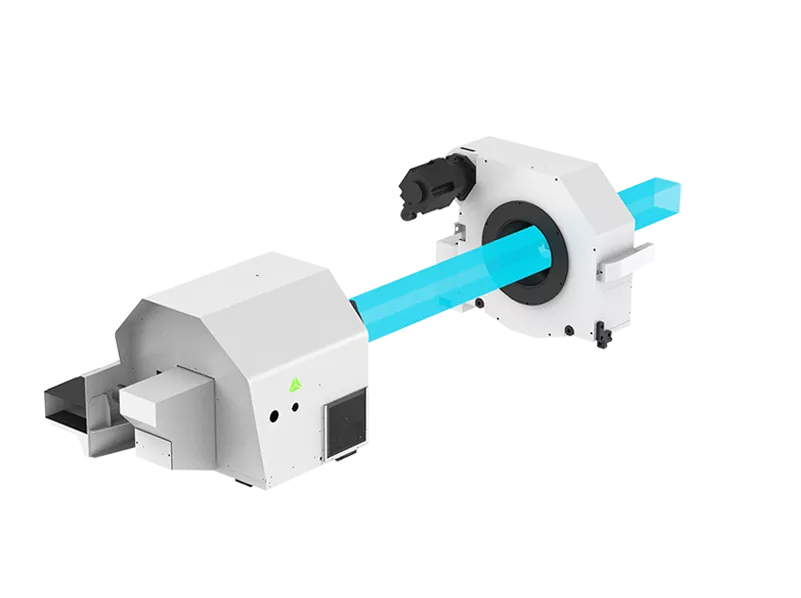

Intelligent Digital Chuck

The chuck can detect the clamping status and the tube size data to achieve self-adjustment of clamping force.

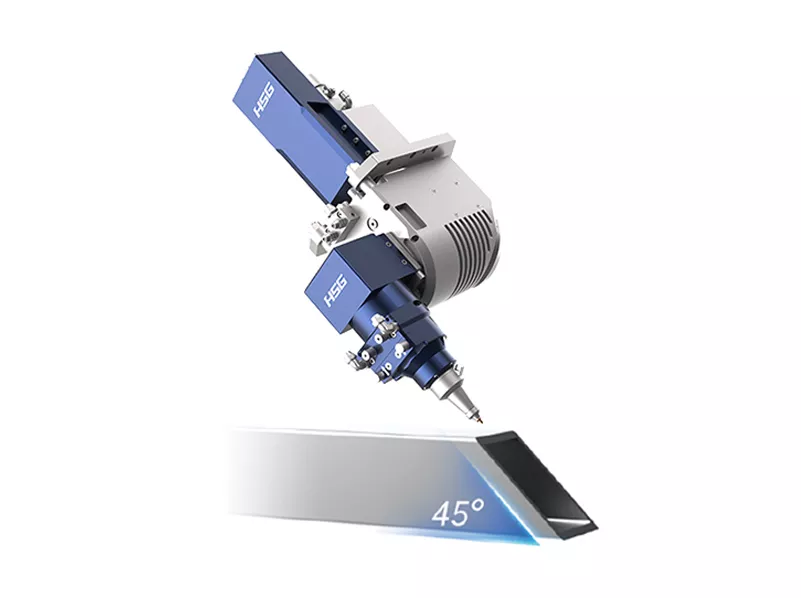

Beveling Processing

HSG-LA4 tube beveling tube cutting head to achieve 0-45°beveling cutting.

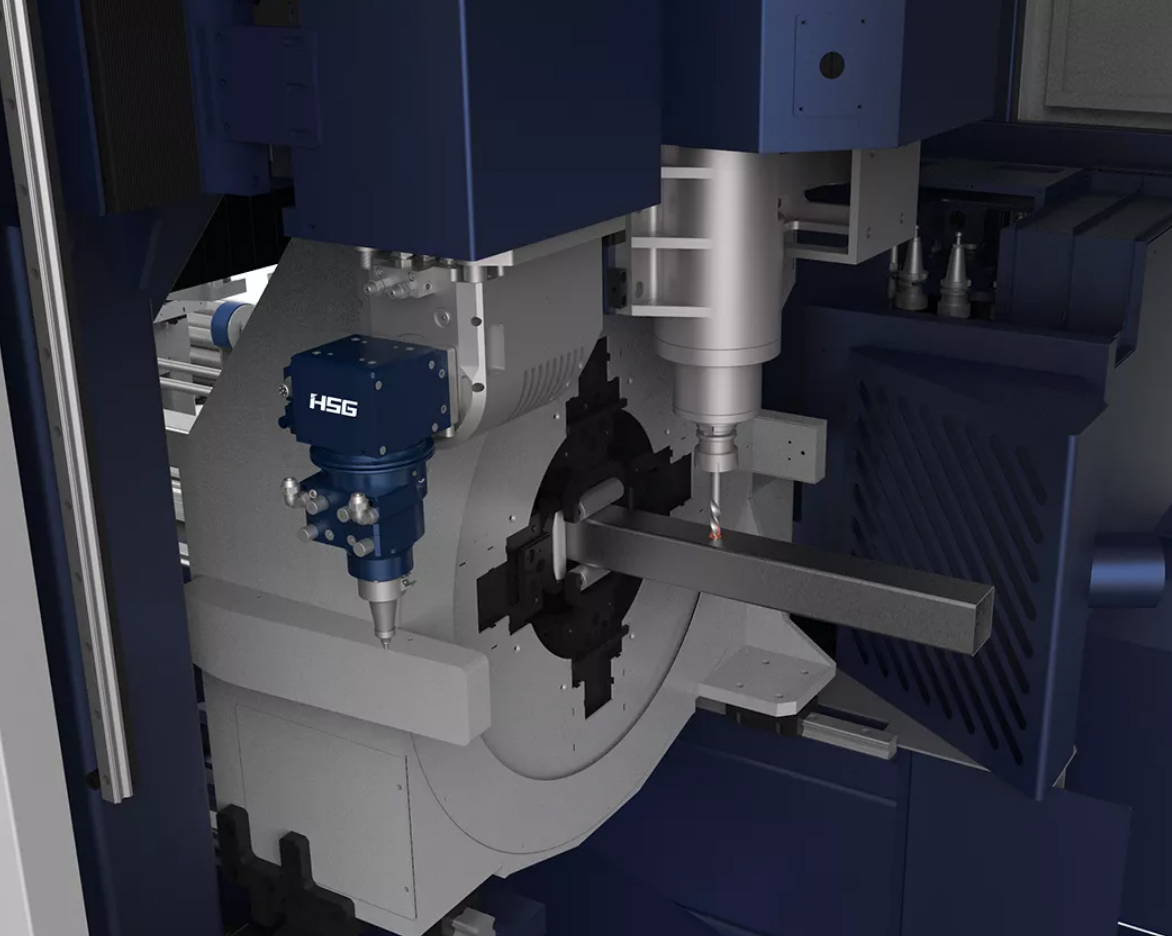

Multiple Apertures Hot Melting -Drilling-Tapping Technique

Self-equipped with tool database to achieve automatic knife shifting.

Technical Parameters