FMW-ECO

Handheld Laser Fiber Welding Machine

Swing Welding Technology

WOBBLE welding heads have the swing welding model which the facula can be adjusted with strong welding fault tolerance. The technology can compensates for the disadvantage of the small laser welding machine spot and extends the tolerance range and weld width of the machined part to obtain a better weld formation.

Work-piece welding in one operation

Simple to operate and easy to train. The work-piece can be welded in one operation. The laser head is light, flexible and can weld any part of the work-piece, making welding work more efficient, safe, energy efficient and environmentally friendly.

Dual Temperature and Control chiller

The Laser Welding Machine is self-equipped with dual temperature and control chiller for constant temperature control heat dissipation and ensuring the core optical components heat dissipation with fiber laser, which are stable and efficient.

Handheld Welding Laser Head

Handheld welding laser head with ergonomic design and light weight can be operated easily and persist in working.

Technical Parameters

Main Functions of a Laser Welding Machine:

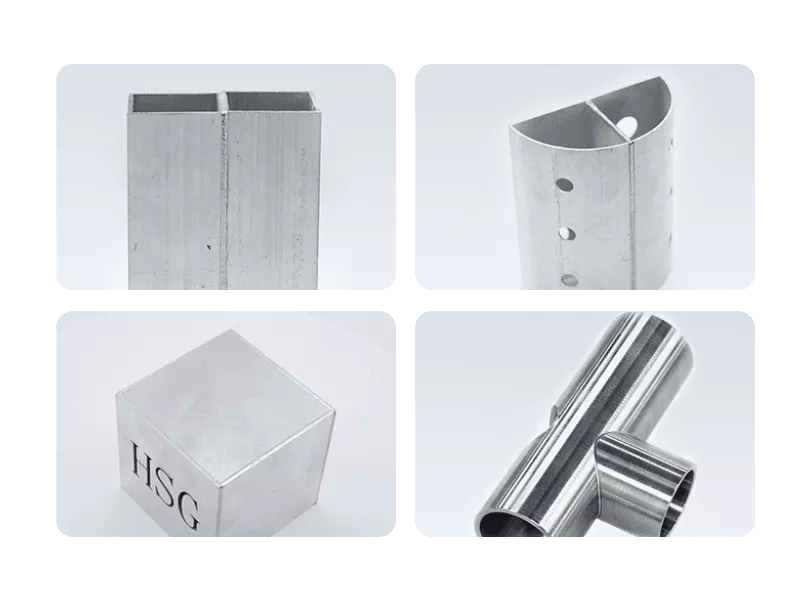

- Joining Materials

- The primary function is welding: it fuses materials by heating them with a laser beam until they melt and merge.

- Commonly used for metals (like steel, aluminum, titanium) and some plastics.

- Precision Welding

- Ideal for applications where tight tolerances are required, such as in electronics, medical devices, and automotive components.

- Capable of producing narrow, deep welds with minimal distortion.

- Automation & Repetition

- Laser welding machines can be easily integrated into automated manufacturing systems, such as robotic arms or CNC machines, for high-speed, repeatable operations.

- Non-Contact Process

- Since the laser doesn’t physically touch the material, there’s less wear and tear on the equipment and no contamination of the materials being welded.

- Welding Difficult-to-Reach Areas

- The focused laser beam can reach tight or complex geometries that are difficult to access with traditional welding tools.

- Micro and Macro Welding

- Useful in both microscopic applications (like in microelectronics) and large-scale welding in aerospace or automotive industries.

✅ Key Benefits of a Laser Welding Machine:

- High welding speed and accuracy

- Clean, minimal-spatter welds

- Low thermal distortion

- Suitable for delicate or heat-sensitive parts

- Flexible and programmable for complex patterns