TL350 II SERIES

Heavy-duty Tube Laser Cutting Machine 3000W-6600W

Weight of Single Tube 600kg

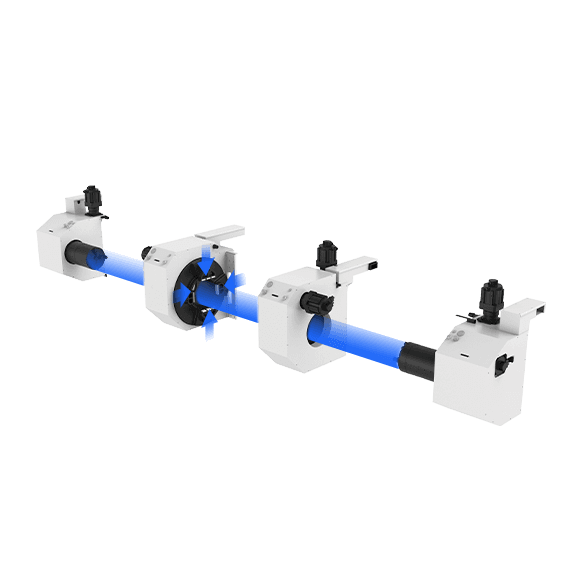

Four Pneumatic Chucks

Cut up to 12000mm Entire Tube

Φ325mm Round Tube

HSG-X9800 Intelligent Control System

As the fifth generation, HSG-X9800 is specially developed for our machines equipped with four chucks.

21.5-inch Touch Screen

Built-in tube graph database, no programming required

Create cutting records and reports automatically

Show special-shaped tube graphs and routes in a more intuitive way

Enter its program by clicking anywhere

Four Pneumatic Chucks

With automatic centering and big clamping force, the chucks can maintain an easy and steady clamping of heavy tube.

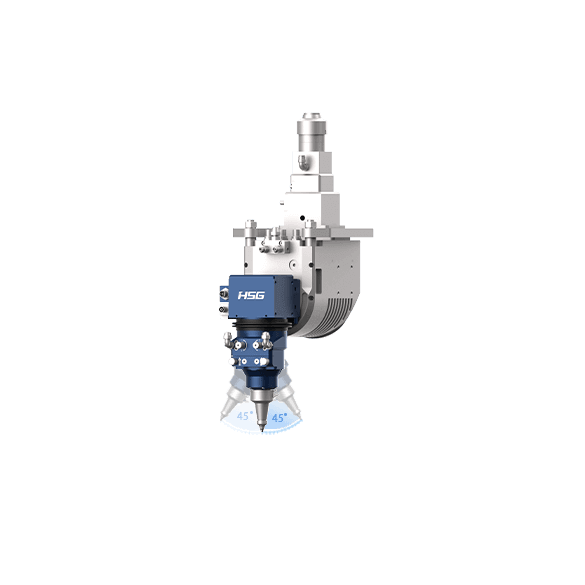

Optional 3D Five-axis Cutting Head, 45° Bevel

Self-developed by HSG LASER

Angle of swingable axis ±160°

OD motor with up to 3600°/s acceleration and ±/-6.1’’ precision

Protect itself from any possible collision thanks to its equipped electromagnetic coupling anti-collision device

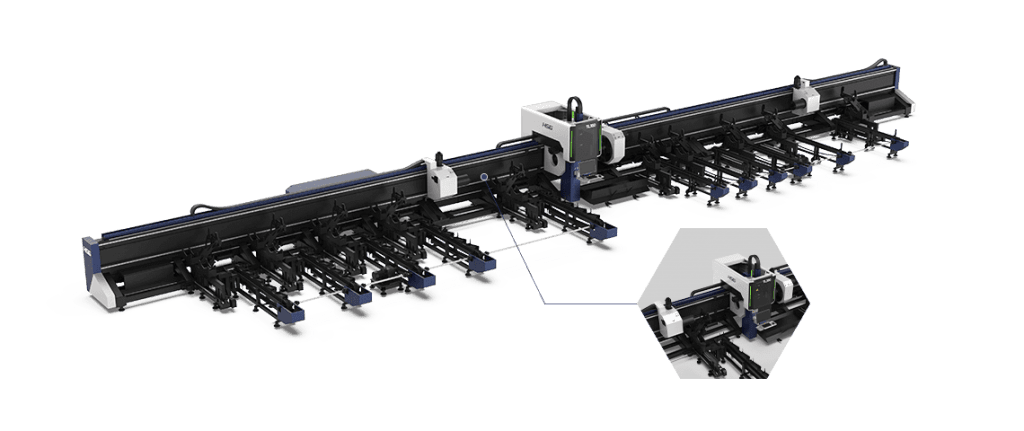

Side-attached Machine Bed

The machine is outfitted with side-attached machine bed that is convenient for loading and unloading heavy tube, during that process, machine bed and guide rails are not destroyed by collision.

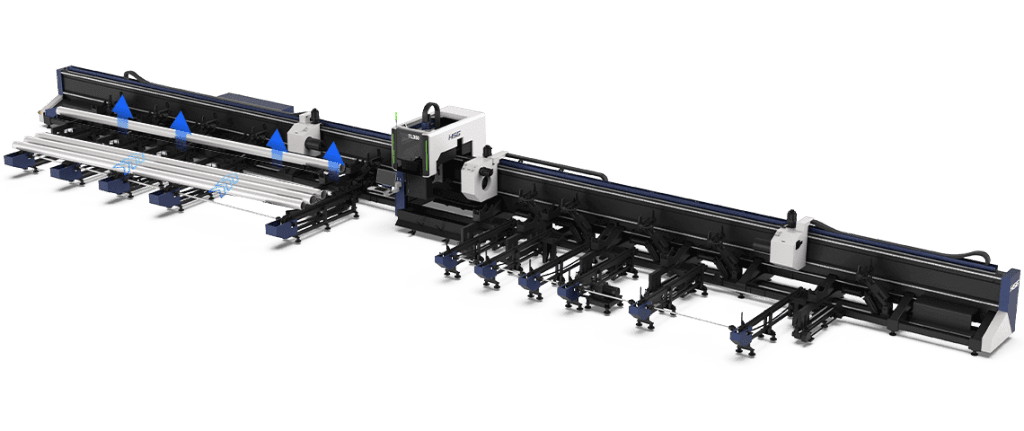

Automatic Loading & Unloading System

The machine only needs to be operated by 1 worker while loading heavy tube. Loading is in syn with unloading, without any unnecessary shutdown and tubes will not collide with each other, preventing deformation.

Technical Parameter

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine.

Cutting Samples