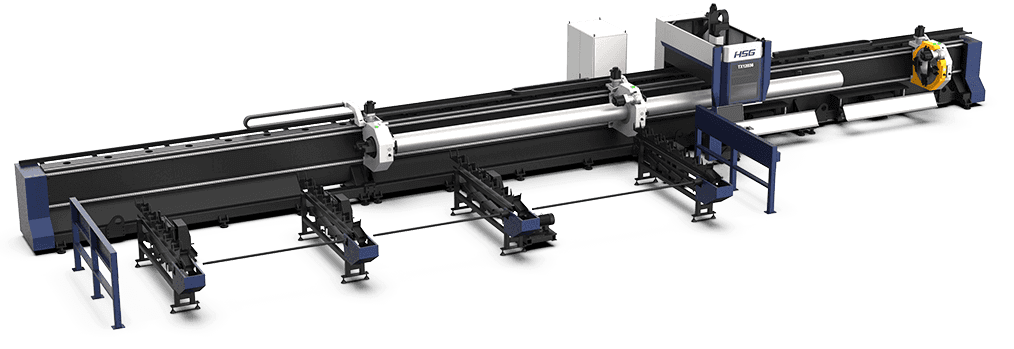

TX SERIES

Heavy-duty Tube Laser Cutting Machine 3000-6600W

Weight of Single Tube 1500kg

Length of Single Tube 12000mm

Cut Φ500mm Round Tube

Cut with 45° Bevel (Optional)

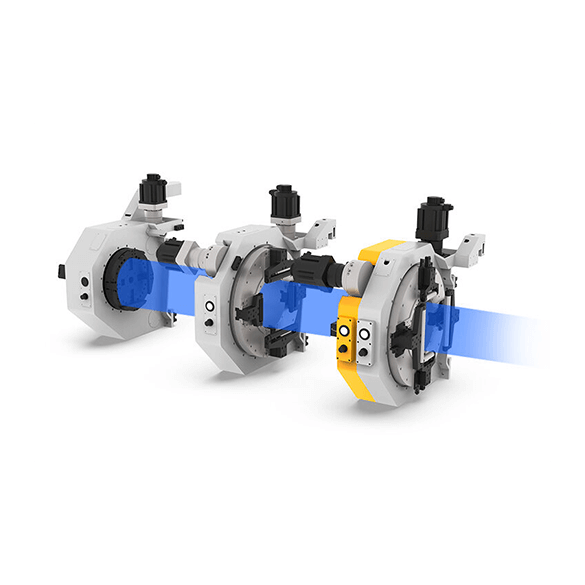

Chuck Clamping Technology

Chuck C3 and C4 are combined as one and can rotate or move synchronously but control its claws opening and closing independently. Except for clamping, tube supporting is also available for the combined chuck, remedying the common weakness of four chucks.

Both tube clamping and supporting

Correction of tube deviation

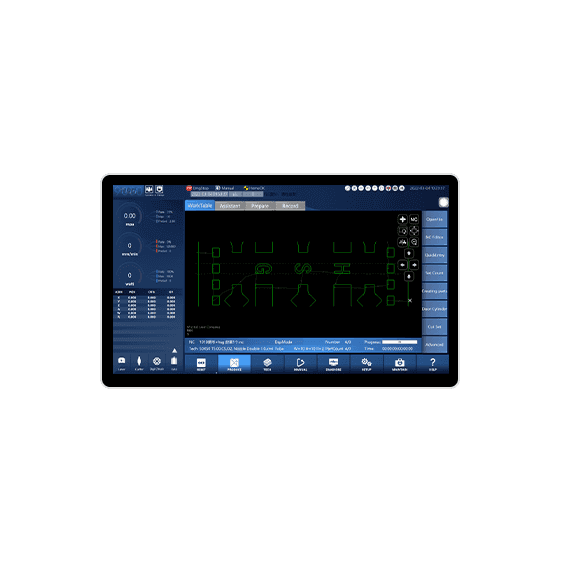

HSG-X9800 CNC System

As the fifth generation, HSG-X9800 is specially developed for our machines equipped with four chucks.

21.5-inch touch screen

Built-in tube graph database, no programming required

Create cutting records and reports automatically

Enter its program by clicking anywhere

Show special-shaped tube graphs and cutting routes in an intuitive way

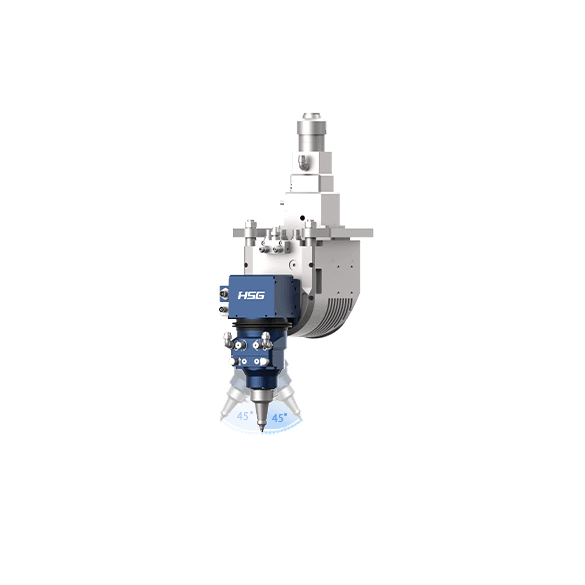

Optional 3D Five-axis Cutting Head, 45° Bevel

KLINGE, made of stainless steel, has a function of water cooling, dual-path cooling nozzle, ceramic ring, double focusing protective lens, drawer-type pluggable protective lens, focusing and collimating lens.

Self-developed by HSG LASER

Take control of laser focus thanks to its fully automated servo motor

Laser path reshaping technology

Swingable head outfitted with the function of collision prevention

Modular structure in favor of repair or maintenance

Labor-saving Configurations

* Multi-tube Automatic Loading Device

Several heavy tubes are usually loaded synchronously.

* Automatic Unloading Equipment

Two follow-up turning plates are available to convey ≤6000mm heavy tube stably from high to low while unloading, so that tube surface is well protected.

Technical Parameter

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine.

Cutting Samples