GV-B SERIES

High-power Bevel Laser Cutting Machine 12000-30000W

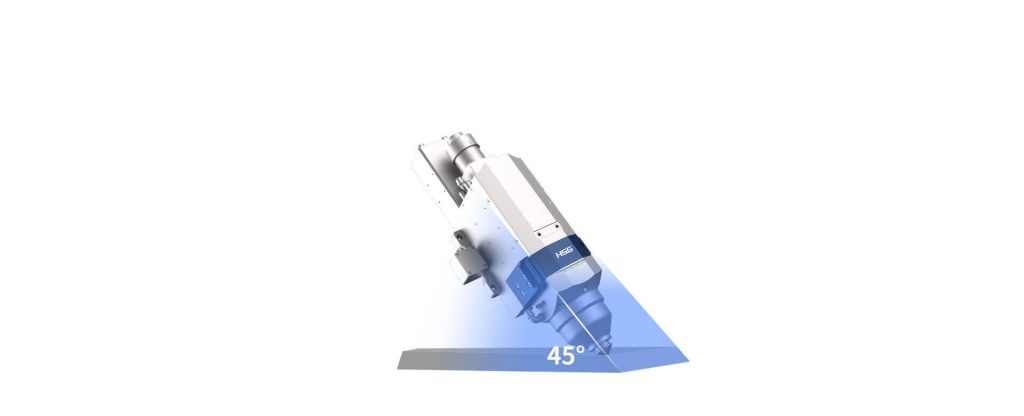

Cut 45°Bevel

Cut 100mm SS and AL alloy

HSG-NEST Nesting Software

Cold-drawing Extrusion Aluminum Beam

Once Forming of 45° Bevel

P10/P20/P30 cutting head works in conjunction with Alpha T bus CNC system to break through conventional 0° straight section and make 45° bevel possible. Standard-, V-, K-shaped bevel can take shape only once.

P10/P20/P30 Autofocus Laser Cutting Head

It can change its laser spot to proper size and shape according to cutting materials and thickness.

Active obstacle avoidance, automatic cooling down

Optical filming, visual display of temperature and pressure

Anti-pollution design, cut with mirror-like surface

Remind of regular maintenance, give early warning if abnormal

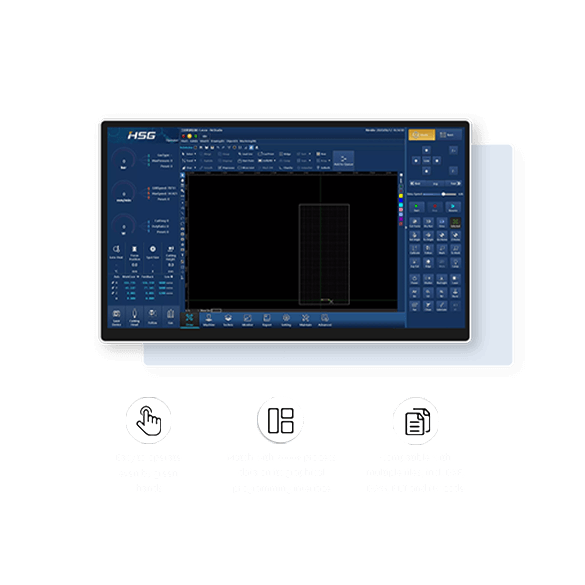

Alpha T Bus CNC System

Alpha T can make data transmission via a network cable.

Micro-connection cutting

Active obstacle avoidance

Real-time monitoring of core components

Active reminder of machine maintenance

HSG-NEST nesting software

*Bus refers to data transmission mode via on-site bus control system.

Double Exchange Platforms, Taper Pins Positioning

The double platforms are driven by double motors and 16A wide chains and positioned by taper pins. The entire exchange process is shown on PLC touch screen.

Patented Ventilation System

* Full-protective Design

Top cover is provided and pneumatic safety door is installed between exchange platforms to prevent smoke dispersion.

* Zoning Ventilation

Divide cutting area into left and right zone, outfitted with butterfly valve dampers and outboard 300*300mm full-hollow ventilating ducts

* Positive-pressure Blowing

Blower fans on its top cover and beam offer positive-pressure blowing to press cutting smoke below machine bed.

Technical Parameter

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine.

Cutting Samples