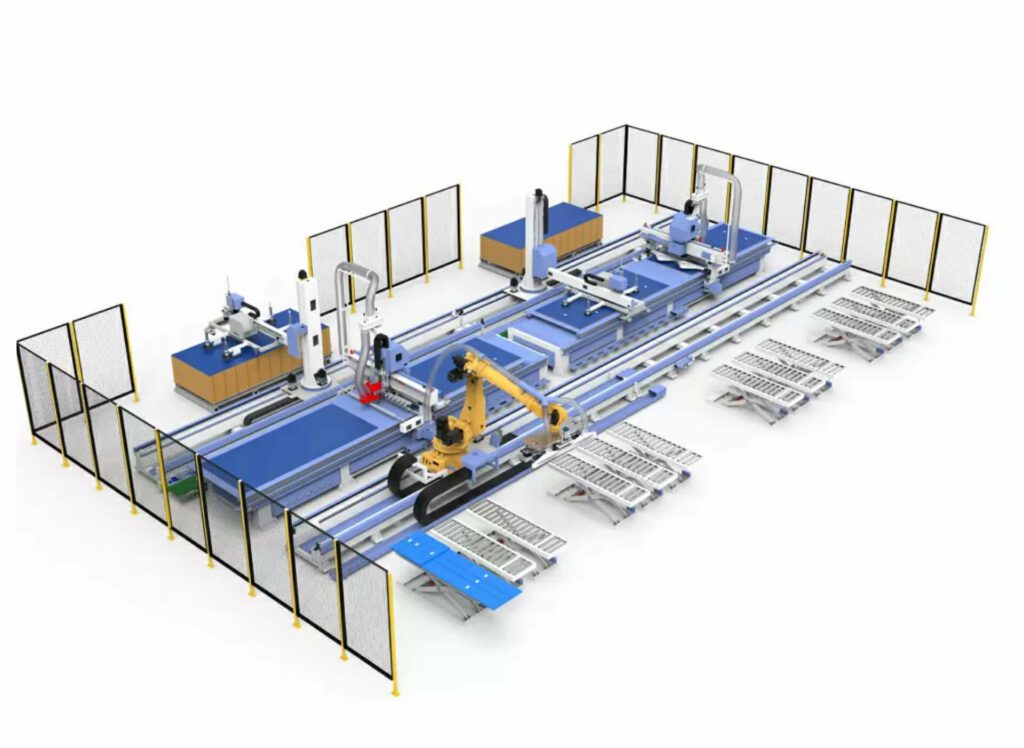

Fully automatic furniture cutting workstation to realize unmanned production and improve production efficiency.

Product Description

The traditional panel furniture cutting process mainly relies on manual mode. The main tasks include table dust removal, large board feeding, board dust removal, labeling, board picking, sorting, palletizing, positioning, adsorption, selection of processing procedures, waste disposal, and residual materials. Processing, etc.; due to the emotional nature of people, the uncertainty of personnel management, emotionality, safety and other factors, resulting in unstable production efficiency, poor product quality consistency and safety and other issues, the industry will eventually develop towards an intelligent unmanned model.

The intelligent cutting workstation developed by Quick is based on the high-end double table cutting workstation with high efficiency and strong stability. Replacing a human-based production model with minimal human involvement.

Improve corporate image and gain customer recognition;

Reduced human involvement and simple management;

Continuous production mode, improve equipment utilization, 24-hour uninterrupted production, improve delivery cycle;

Flexible design, can be stand-alone, can be connected, can be connected to MES system;

Production dynamic information can be monitored throughout the process, big data management, traceability, and convenient factory management;

Low investment, acceptable to general enterprises.