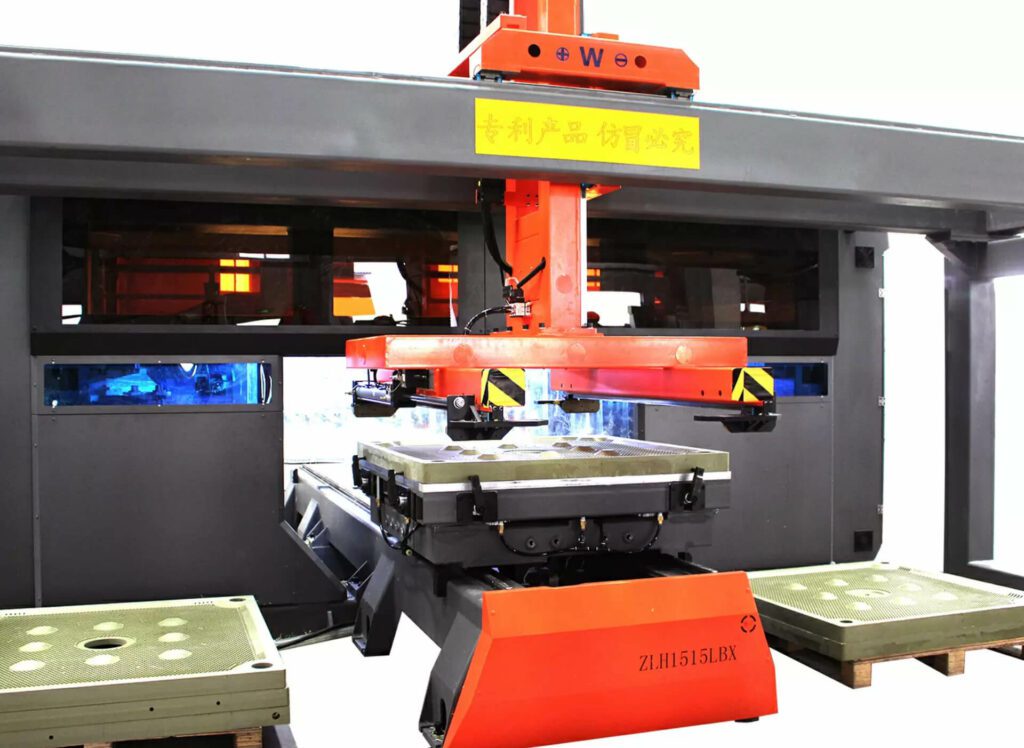

The ZLH1515LBX five-axis filter plate machining center is a patented product independently developed by our company. This structure is the world’s first, subverting the entire industry’s cognition of filter plate processing, and represents the most advanced industry level in the world today. According to the technical characteristics of filter plate processing, this product has independently developed the motor, spindle and operating system for the machine, so that the processed filter plate can be directly connected to the equipment for installation, which truly realizes the intelligent filter plate production mode.

Product Description

Combined with the production process of the filter plate, our equipment is mainly composed of the following parts:

- The automatic loading and unloading part has mechanical gripper and automatic positioning functions, which can automatically execute program processing or semi-automatic operation through the handheld box.

- The movable aluminum alloy processing table has two sizes of 1.25*1.25 and 1.5*1.5 meters, which can be switched automatically. The left and right sides of the front table are the finished product stacking area and the rough storage area.

- The powerful U-shaped 5-axis machining center is equipped with 10 disc tool changes + 2 linear tool changes to cope with different machining processes

- Automatic revert function, which can realize the A and B surface processing of the workpiece at one time

Video

Accessories and Advantage

The ZLH1515LBX 5-axis filter plate processing center is the third-generation product independently developed by our company,it has won a number of national design patents and utility model patents. It embodies the wisdom and hard work of intellectuals. This product is a disruptive innovation and a milestone in the process upgrade of the filter plate processing industry influences. Currently, its outstanding contributions include:

- Save labor and increase productivity

- Save at least 90% of labor costs and increase production capacity by more than 8 times. At present, the equipment realizes fully intelligent operation. One operator can operate 3-5 pieces of equipment at the same time. One piece of equipment can process 3 filter plates per hour. If one worker operates 4 pieces of equipment at the same time, the calculation is It can process 12 sheets per hour, which is equivalent to processing one sheet in 5 minutes. In the past, at least 10-15 people were required to process a filter plate, and a maximum of 1.2 filter plates were produced per hour. Through data comparison, it can be seen that the production line has saved more than 90% of labor and increased production capacity by at least 8 times.

- Reduce land occupation

- The entire production line of the new product covers an area of about 42 square meters, while in the past it required at least several hundred or even thousands of square meters. It greatly saves floor space and other auxiliary equipment (such as cranes, forklifts, etc.).

- Completely eliminate the hidden dangers in the process of processing. The whole process realizes intelligent and fully automated processing without human involvement, so the safety is extremely high.

- The standardization of products has been fully realized. Greatly improve the technical indicators and service life of the filter plate.