1.If use the plasma cutting machine to cut the the thick meal, have to use the arc height adjust system, while our height adjust system use the high sensor, one minute can send out 12,000 signal per minute.

2.We equipped the two fan for take the cutting smoke out from the room.This way, will efficiency to let the workshop in the good environment.

3. The painting: all our machine body have been processed by professional anti-rust treatment. First, we spray 2 times anti-rust paint to ensure that all parts of the machine in a fully protected state, and then spray color. This can effectively prevent the machine rust, resulting in damage to the machine.

Product Description

Cnc plasma cutting machine also called plasma cutter, and plasma cutting is a processing method that uses the heat of a high-temperature plasma arc to partially or partially melt (and evaporate) the metal at the incision of the workpieces and uses the momentum of the high-speed plasma to remove the molten metal to form an incision. plasma cutting machine including portable plasma cutter, or table plasma cutting or with rotary device

Parameter

Accessories and Advantage

Machine body design

Machine mechanics design,Invited the famous university physics professor of the design of the machine,The middle of each beam has a column, strengthen the support of the bed effect. For the magnification, thick, heavy metal plate,Can effectively prevent the middle of the machine due to lack of bearing capacity caused by the deformation of the machine.

However, many other manufacturers in order to save material costs, eliminating this part, resulting in prolonged use of the machine deformation.

Double suction

we equipped the two fan for take the cutting smoke out from the room , front fan will blow to back , the back fan will exhaust the smoke out from the machine and out from the room . This way ,will efficiency to let the workshop in the good environment . While other factory does not have this fun or only have one .

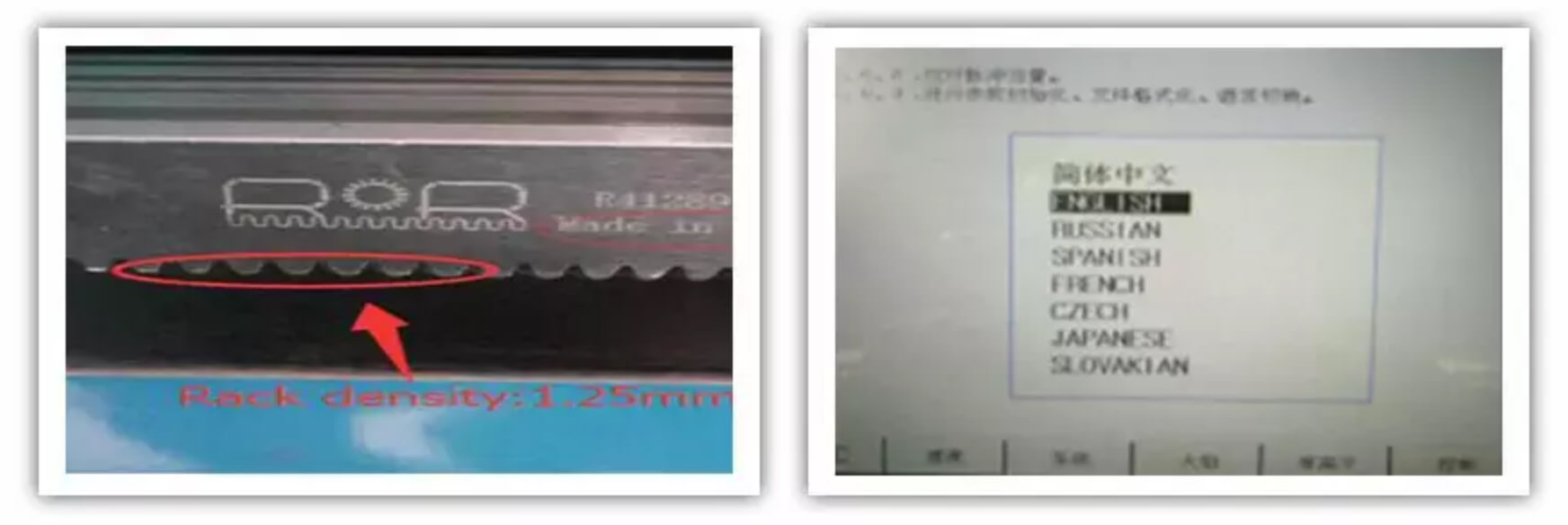

Rack

the teeth of our racks (ie, the distance between the two teeth) are 1.25 mm, while the other manufacturers are 1.5 mm. So that our machine cutting accuracy is far better than other manufacturers.

Controller

Our control panel it is big (10 inch ) more easy to check the detail menu and in the control system have many different language , such as Portuguese , Japanese,Korean, Netherland , Spanish ,Russian ,French .