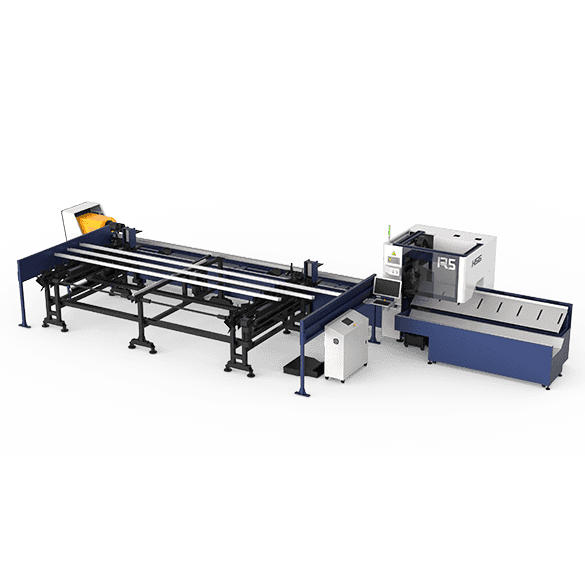

R5 II SERIES

Full-automatic Tube Laser Cutting Machine 1500-4000W

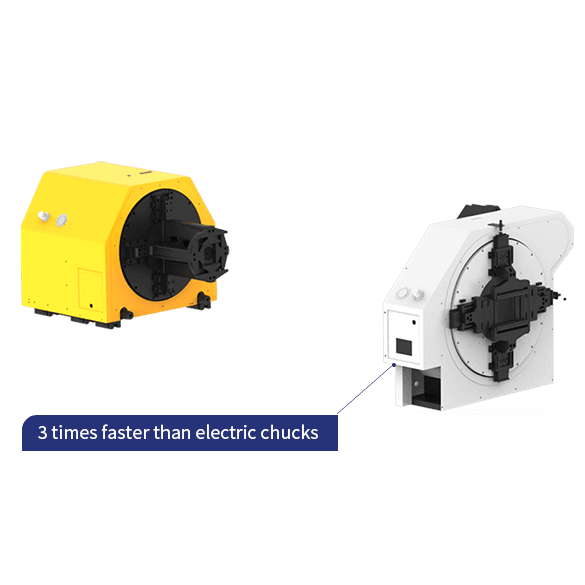

Squircle Pneumatic Chucks

Japanese Takagi Tube Nest (TTN) Software

Scraps Collector

Optional Laser-proof Glass and Safety Light Curtain

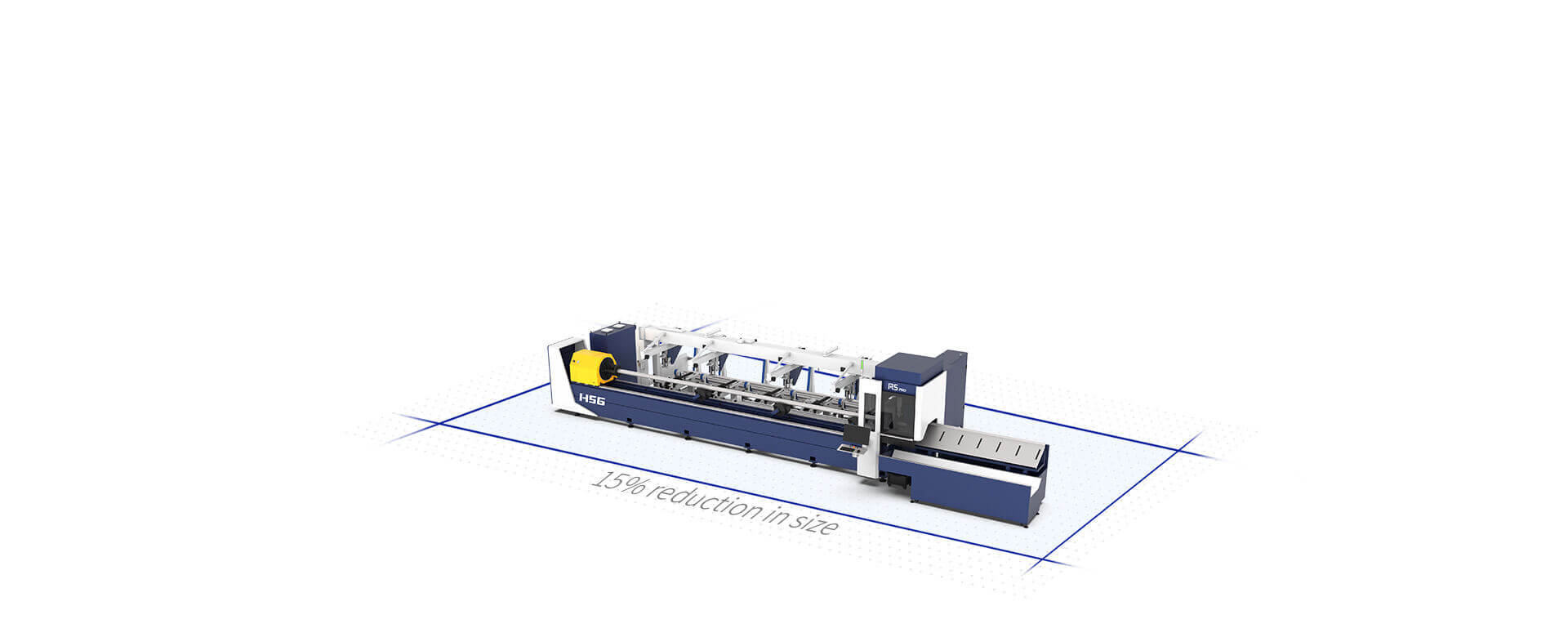

Small Size, Rich Functions

R5 II is 15% smaller in size than same-grade model, TH65 and easily operated in a crowded workshop. It deals with round, square, rectangular tube, as well as angle, channel, H-shaped steel. The weight of single tube reaches 200kg.

HSG-X9000 Bus CNC System

21.5-inch touch screen

Open-and-shut but full-featured user interface

Detect tube deformation automatically, compensate for graphic offsets

Real-time show of power, air pressure, speed and tube graphs

Take integrated control of core components

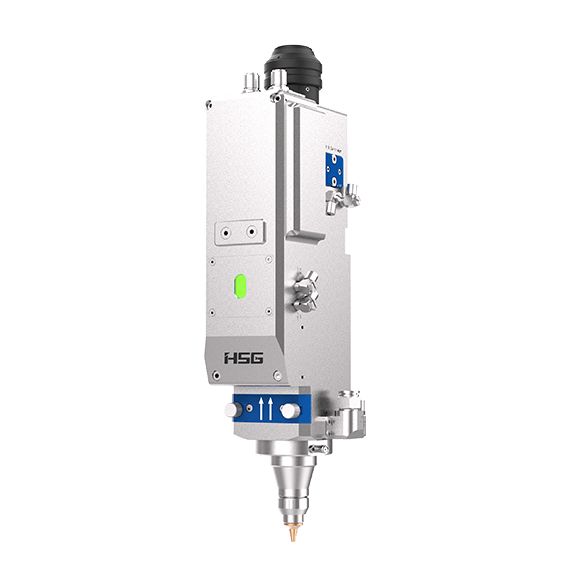

KLINGE Autofocus Cutting Head

KLINGE, made of stainless steel, has a function of water cooling, dual-path cooling nozzle, ceramic ring, double focusing protective lens, drawer-type pluggable protective lens, focusing and collimating lens.

Self-developed by HSG LASER

Autofocus accuracy ±0.01mm

Flow control for mirror-like surface cutting

Prevent spark splashing and scalds by SS protective pipes

Double Squircle Pneumatic Chucks

Automatic centering

Large and constant clamping force to clamp heavy tubes

Expand clamping range of square tubes

Detecting sensor for front and rear chuck opening & clamping

Φ20-240mm

Φ20*20-240*240mm

Tailing length 85mm

Intelligent Production Line

Turning Plates for Unloading

Convey finished heavy tubes stably from high to low while unloading and protect tubes from any possible harm and scratch.

Optional Automatic Loading Device

Fulfil both batch and separate orders

Technical Parameter

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine.

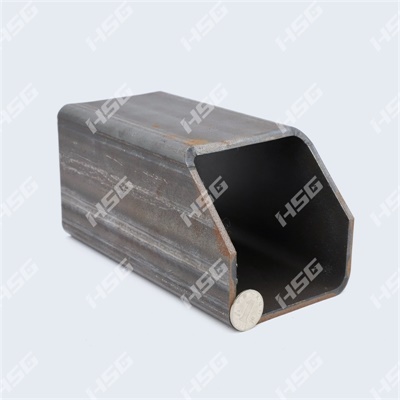

Cutting Samples