TM65 MINI SERIES

Tiny Tube Laser Cutting Machine 1500-3000W

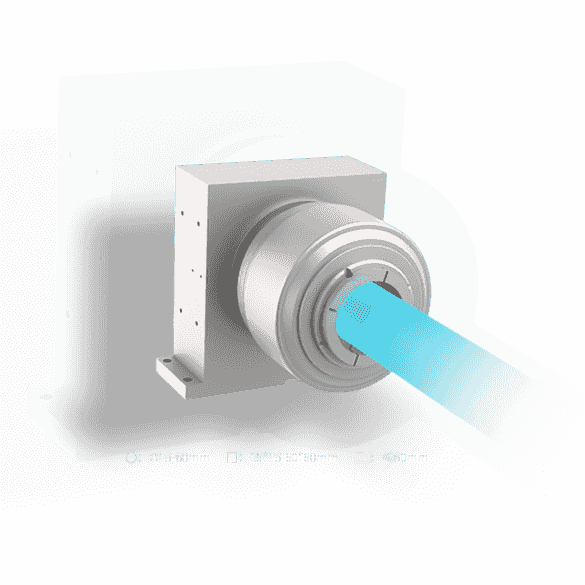

Autofocus Cutting Head

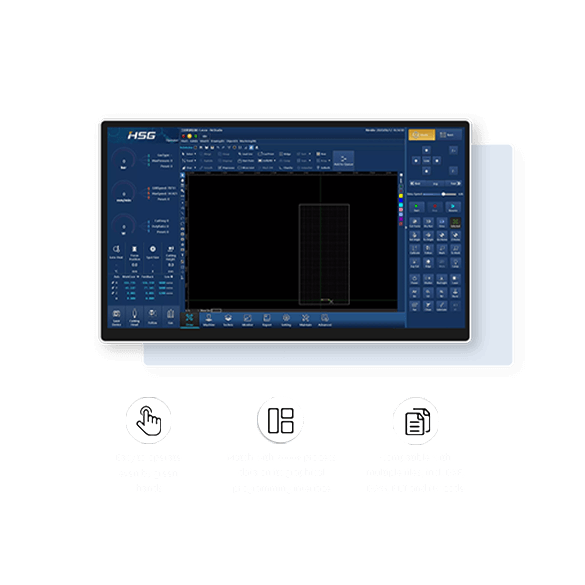

Takagi Tube Nest (TTN) Software

Flying Cutting and Space Leapfrog

Shipped in A 40HQ Standard Container

Pneumatic Chuck

The chuck can protect tube surface from scratch because of its collets equaling to tube diameter.

No-load speed 100m/min

Rotating speed of chuck 150r/min

Acceleration 1.0G

Alpha T Bus CNC System

Alpha T can make data transmission via a network cable.

21.5-inch touch screen

Compatible with IGS files

Real-time monitoring of core components

Active obstacle avoidance

Capacity expansion available due to multiports reserved

* Bus refers to data transmission mode via on-site bus control system.

Cutting with 50mm Tailing

When tube fails to be pushed by loading device for cutting, tubes behind will drive the former to move on, as thus, tailing length is further shortened.

Automatic Loading Equipment

* Tubes are usually loaded to material laying area by transmission mechanism of which limiting device can make tubes in order.

* Tubes are clamped by 6 loading rollers that need no reset in a loading cycle. Therefore, duration of waiting for tubes is decreased.

Technical Parameter

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine.