Cut 3D Special-shaped Thin-walled Metal Workpiece

CELL3015G SERIES

3D Five-axis Laser Cutting Machine 3000W

No-load Speed 170m/min, Acceleration 1.7G

Tailor-made Machining Range

Five-axis Linkage

Gantry Dual-driven Beam

FANUC Five-axis Linkage Control System

The tried-and-tested FANUC works with servo control technology to enable five-axis linkage machining.

One-key start, man-machine interaction

Auto correction of tooling location deviation

Positioning precision of machine bed ±0.05mm

Real-time monitoring of core components

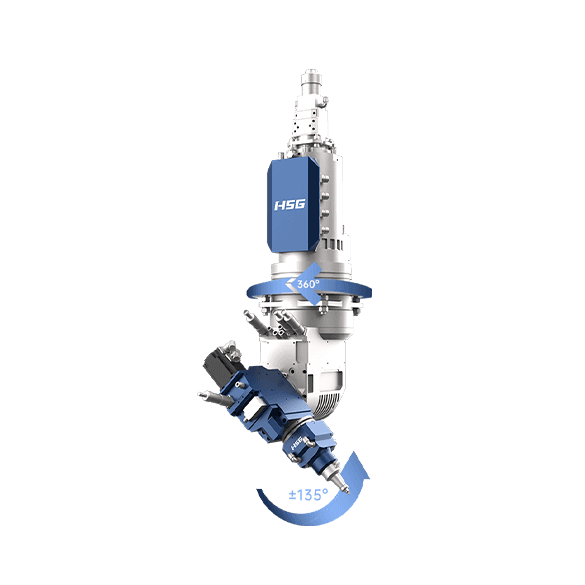

LA5 Five-axis Linkage Cutting Head

Fit for cutting 3D special-shaped workpiece made of SS, CS, AL and Ti alloy.

Move from one plane to anther quickly

Enable customization of moving stroke

Fully-sealed structure, self-adaptive autofocus to cut various sheets of different thickness

360° crash-proof device that helps to protect the cutting head well

N*360° rotation

±135° swing

Repeated precision<0.005°

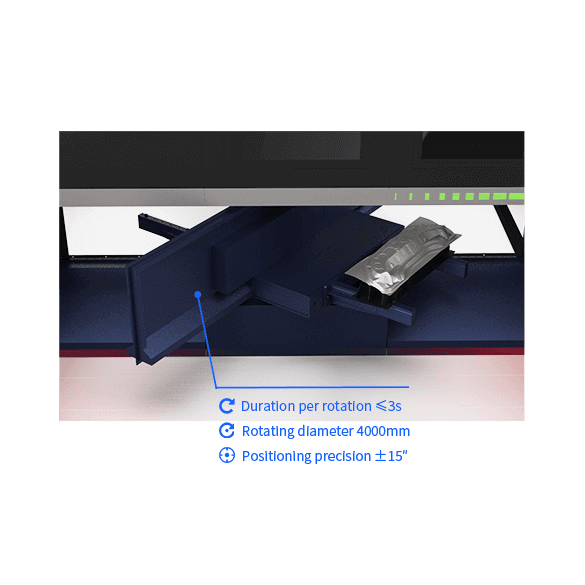

Double-station Turn Table

* Table base welded by using quality steel

* Double stations imported from abroad and driven by servo motor

* Loading and cutting are on duty in turns

* Adjustable quantity of support arms and clamping range of workpiece holder to meet custom-built needs

Safeguard System

Two safety doors enable fully-sealed work and entry into work area from left and/or right

CCD monitoring cameras and display screen to show real-time cutting state

Ventilating and dusting channel

Photoelectric sensing curtain, protecting operator and machine

Technical Parameter

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine.