HB-G1 SERIES

Oil-electric Hybrid Bending Machine

Two-way Convex Deflection Compensation

Hydraulic Oil Consumption 76L

Various Upper and Lower Tools

Optional Collaborative Robot

Italian ESA S650 Operating System

Energy-saving Technology

Carbon Steel Welded Frame

Its slide block, lower platform, left and right column are subject to finite element mechanical analysis. As thus, the overall bending precision will be kept within 0.5°.

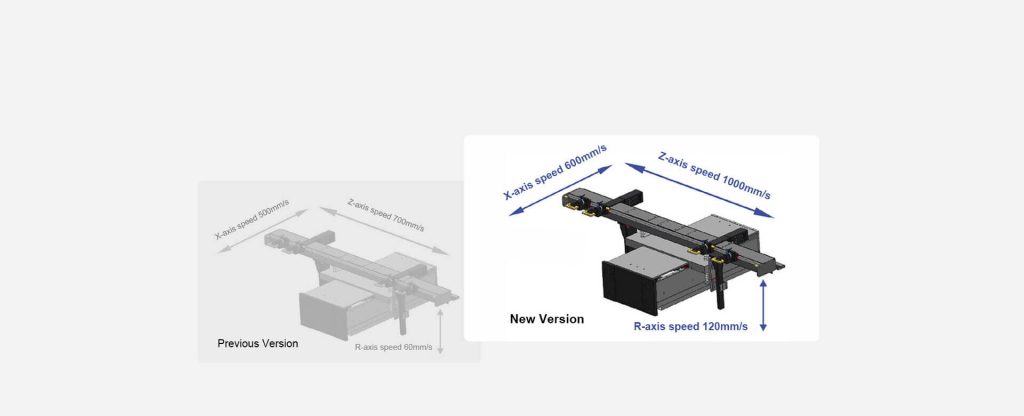

Post-positioning System

Backgauge can move at the speed of 1000mm/s. The slide block will lift and fall at the speed of 200mm/s. The bending speed reaches 15mm/s.

Further Expansion of Processing Range

Its open height and stroke of slide block are raised to 520mm and 250mm respectively. In combination with 420mm (depth) throat, the bending range is further expanded. Time spent on taking out bending workpiece is reduced and any possible scratch is prevented.

German COMAU Six-axis Collaborative Robot (Optional)

Automation interface is provided for upgrades anytime.

Technical Parameter

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine.

Bending Samples