1.Guided multi functional control interface, pneumatic control, no manual tool adjustment, feed speed of the fastest 30m / min, easy to use, no special post skills training.

2.The equipment is equipped with a pre-milling device, which can effectively repair the roughness of the incision when cutting, the cut is more flat, and the edge is naturally pasted more, making the glue water line more invisible.

3.High speed tracking this equipment adopts the high-end configuration of four knife tracking, even when the equipment is running at high speed, it can still achieve accurate tracking (chamfer / fillet) effect stably.

Product Description

High Cost Performance Fully Automatic Edge Banding Machine Fk83,this equipment has rich functions of high quality, can provide high quality edge sealing effect.The maximum feed speed of this machine can reach 30m/min, and the high efficiency production is further pushed to the maximum. Even in the face of high-quality large-scale orders, we can still face it calmly, and the delivery time is fast.

Parameter

Accessories and Advantage

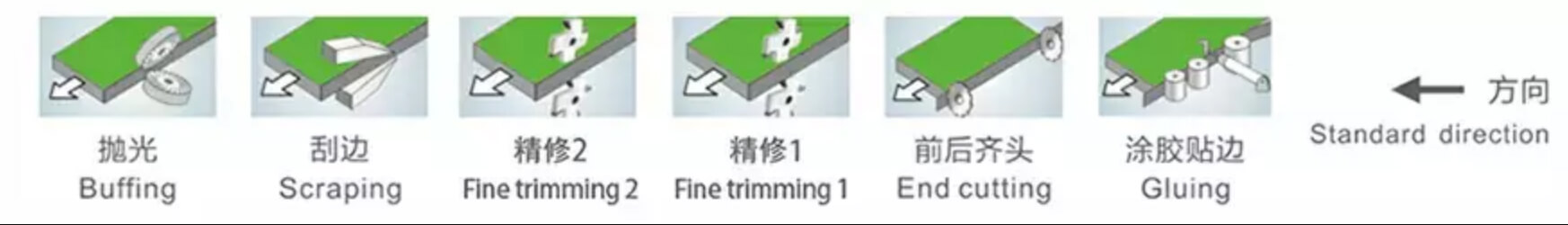

Separator unit

It has the function of separation and solves the problem of hot melt glue polluting the board surface after gluing.

Pre-milling

After milling by milling mechanism, all kinds of defects on the machined surface can be removed, and the edge sealing can reach the best state.

Gluing system

Reasonable control of glue quantity, good thermal conductivity, stable operation, uniform coating, firmer adhesion and more perfect edge sealing effect.

Six pressure wheel pressing

Strong pressing force, edge banding is more suitable, scraping off the excess hot melt glue, making the glue line smaller and the edge banding effect more perfect.

Double rails end cutting

Fast cutting the front and rear edge banding, two saw blades are matched in front and back to achieve high precision and high efficiency.

The automatic oil filling system of the end aligning guide rail extends the service life of the equipment.

Fine trimming

The upper and lower sides of the edge banding are protruded from the upper and lower planes of the board, and the redundant edge banding is trimmed into an R-angle shape, so that the upper and lower edges of the edge banding are flush and smooth with the upper and lower surfaces of the board.

4 cutter corner trimming

The edge fillet (chamfer) of plate is processed to make the four corners of plate smooth and beautiful.

Scraping

Remove the marks left by trimming knife and finish R fillet, pneumatic four position edge scraping, clear division of labor, ensure efficient work, improve work speed.

Broken wire

Clamping broken wire device: solve the problems that the scraping edge ribbon affects the normal operation of the flat scraper, or directly winding the polishing unit causes the motor to be stuck and burned.